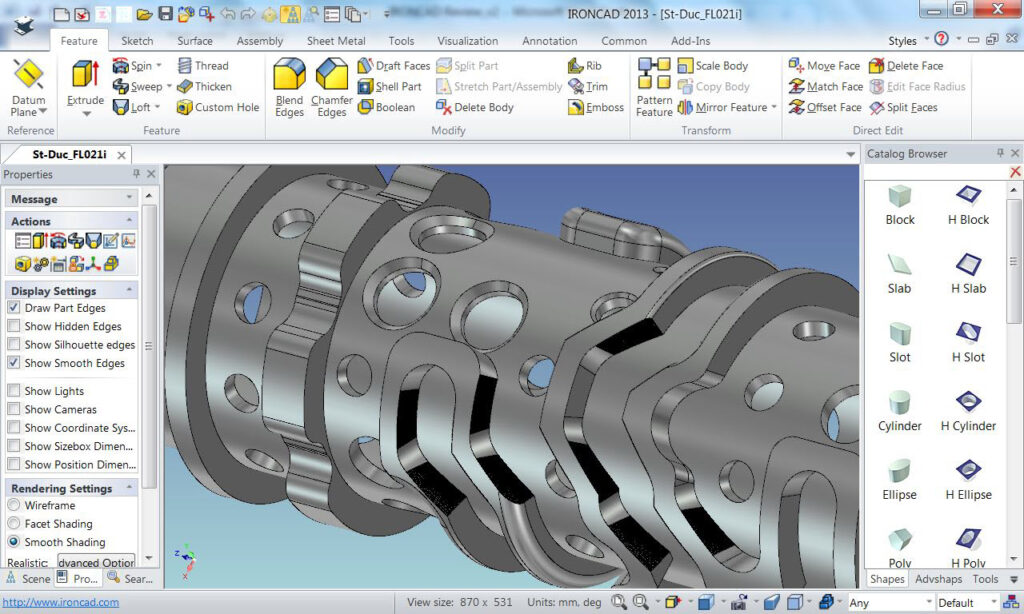

A Very Different Design Tool – Parametric Design Meets Efficiency. Ship building, aerospace, automotive, general manufacturing and its outstanding assembly capabilities, best of class.

IronCAD:

User Interface (UI): IronCAD is designed to be more intuitive for users who are new to 3D CAD. Its unique drag-and-drop functionality allows for fast component placement and manipulation. This makes it particularly appealing for users who prefer an easy, visual method of working with 3D models.

Valuable Benefits:

- Learning Curve: IronCAD tends to have a more shallow learning curve compared to SolidWorks, thanks to its simpler interface and fewer required steps for basic operations. Users can start building parts and assemblies quickly without needing extensive training.

- Design Flexibility: IronCAD emphasizes direct modeling and ease of modification, which allows users to quickly adapt and change designs. It supports parametric modeling but integrates a more flexible approach, making it easier for users to change models without breaking constraints.

- Design Approach: IronCAD combines parametric and direct modeling, offering flexibility in how designs are created and modified. This approach is particularly useful for users who need to work on conceptual designs and prototypes quickly.

- Assembly Management: IronCAD offers an intuitive assembly management system that allows users to easily drag and drop components into place. It also provides advanced visualization tools to simulate motion and interactions between parts.

- Compatibility & Integration: IronCAD supports a wide range of file formats and integrates well with other CAD systems, which makes it adaptable in mixed software environments.

- Visualization & Rendering: IronCAD offers solid rendering capabilities, with both real-time visualization and higher-quality photorealistic rendering available. The software’s visual style makes it easy for designers and clients to understand concepts quickly.

Ship building components can be instantly accessible from its internal catalogs. This allows for streamlined design, rapid and powerful modeling and editing capability.

IronCAD uses its extensive part catalogs to increase ease and speed of modeling, in addition to providing utilities difficult to achieve with alternative design solutions.

CAD Comparison for Boat Building & Large Assemblies

This comparison highlights key differences between IronCAD, NX, and SolidWorks specifically for boat building and large assembly projects. It focuses on performance, cost, and ease of use at scale.

| Feature / Factor | IronCAD | NX (Siemens) | SolidWorks (Dassault) |

| Core Architecture | Single-scene file (all parts & assemblies in one file, minimal dependencies) | Multi-file, feature/history-based | Multi-file, feature/history-based |

| Assembly Performance | Handles 100k+ parts without major slowdown; no mate overhead | Strong, but rebuilds slow with very large assemblies; tuned for enterprise use | Struggles beyond ~20k parts; heavy mate and rebuild overhead |

| Modeling Approach | Hybrid direct + parametric; drag & drop catalog features; TriBall 3D manipulator | Fully parametric, feature-driven; robust but complex | Parametric, feature-driven; good for smaller assemblies |

| File Handling | One file = simpler management; fewer broken links | Many files + PLM (Teamcenter) integration required for best workflow | Many files; frequent broken links in large assemblies |

| Learning Curve | Easier, more visual (direct manipulation) | Steeper; enterprise-level complexity | Moderate; more user-friendly than NX |

| Best Suited For | Machinery, fabrication, large assemblies, boatbuilding, custom equipment | Aerospace, automotive, enterprise-scale PLM integration | Small to mid-size product design; consumer products |

| Cost Structure | ~$5.7K one-time + $895 annual maintenance | $8K–12K+ per seat annually (subscription) | ~$4K–6K annually (subscription) |

| Graphics/Speed | Lightweight graphics engine; optimized for large models | Heavy but powerful, requires workstation-grade hardware | Often bogs down with complex geometry |

| Flexibility | Import, edit, and mix Parasolid & ACIS geometry seamlessly | Parasolid kernel only; imports well but rebuilds can choke | Parasolid kernel; imports OK but high feature-dependency |

| Boatbuilding Advantage | • Handle entire hull & outfitting in one scene • Fast positioning with TriBall • Minimal file clutter | • Very accurate surfacing • High cost & heavy IT/PLM footprint | • Affordable and widely known • Struggles with large hull assemblies |

For Assemblies, IronCAD is simply the best solution available today. Its ability to work with very large assemblies all in one file with ease coupled with its catalog based design, speed and ease of use, makes it the product of choice for design for 2025 and beyond. Try it, you will be amazed. Solidworks users when first using IronCAD simply can’t believe how these attributes make product design a more powerful and fast process.

Key Takeaway for Boat Building Customers Requiring Large Assemblies…

• IronCAD = Best in class for speed and simplicity when handling very large boat assemblies, layouts, and outfitting without bogging down.

• NX = Most powerful but overkill for most boat builders (high cost, IT overhead).

• SolidWorks = Good mid-level tool, but chokes on boat-scale assemblies.

IronCAD for Machine Design

IronCAD For Sheet Metal

Call for a 30-day evaluation of IronCAD’s sheet metal powerful solution.

Questions…(800) 960-1316

info@ati4d.com

All Rights Reserved Automated Technologies Intl 2015-2026